According to RIPI, Sepehr Seddighi, the director of the Catalytic Reaction Engineering Group at RIPI, said: "One of the processes used to remove hydrogen sulfide and other sulfur compounds is the Claus process which is of great biological importance, and since catalysts based on titania and alumina are the main materials used in the reactors of this process, the evaluation and proper selection of these catalysts is key in making and using them in similar conditions.”

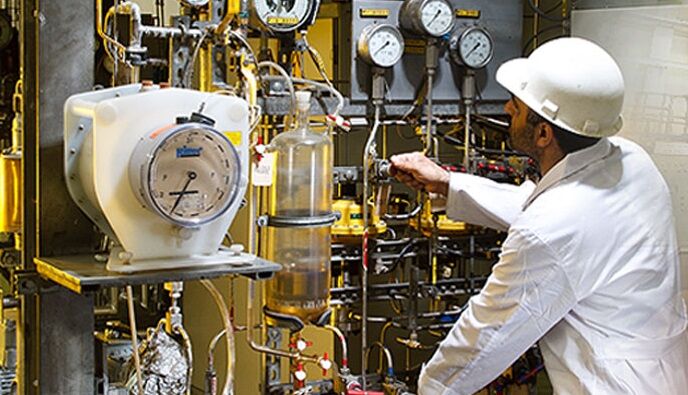

He added: "In order to advance the goals set in the field of this process, the first evaluation pilot plant of these catalysts has been designed, manufactured and launched in the Catalyst Technologies Development Research Institute of RIPI.”

The official further said that the plant allowed for complete evaluation of all the catalysts used in the Claus processes of the petroleum industry.

The Claus process is the most significant gas desulfurizing process, recovering elemental sulfur from gaseous hydrogen sulfide. First patented in 1883 by the chemist Carl Friedrich Claus, the Claus process has become the industry standard.

The multi-step Claus process recovers sulfur from the gaseous hydrogen sulfide found in raw natural gas and from the by-product gases containing hydrogen sulfide derived from refining crude oil and other industrial processes. The by-product gases mainly originate from physical and chemical gas treatment units (Selexol, Rectisol, Purisol and amine scrubbers) in refineries, natural gas processing plants and gasification or synthesis gas plants. These by-product gases may also contain hydrogen cyanide, hydrocarbons, sulfur dioxide or ammonia.

Your Comment