Since 2018, when foreign companies were fully banned from cooperating with Iranian companies and petrochemical imports and exports were slapped with tough bans, the petrochemical industry has hit records as new petrochemical plants have become operational. More importantly, the petrochemical industry has been the top hard currency earner and managed to remove part of financial restrictions under conditions of sanctions.

A Unique Golden Year

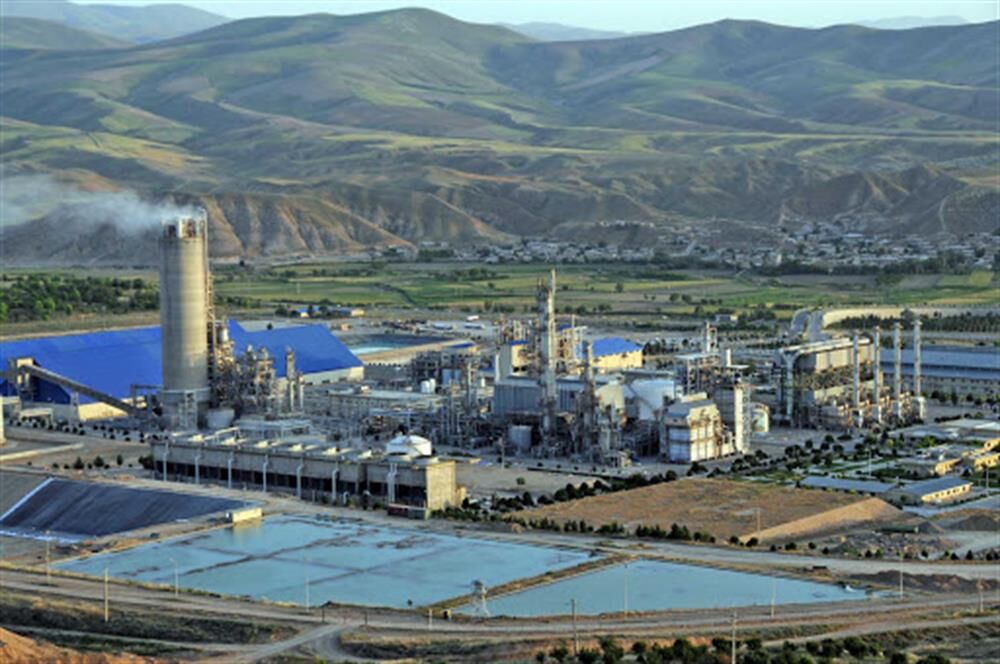

Last calendar year was a unique year for the petrochemical industry. Seventeen projects became operational under the third jump, leading to a 25-million-tonne increase in the petrochemical production capacity in one year. The 17 petrochemical projects required $11.4 billion in investment, which helped raise the petrochemical production capacity from 65 million tonnes a year before to 90 million tonnes last calendar year. That was while the coronavirus pandemic was added as a second restriction factor to all economic and sanctions restrictions.

The Miandoab, Kaveh, Lorestan catalyst production, Kimia Pars Middle East, Bushehr, Lordegan, Urmia potassium sulfate, Hegmataneh, phase 2 of Ilam, Persian Gulf Bid Boland II gas refinery and Kangan petrorefinery were among projects inaugurated last calendar year. In the current calendar year, Sabalan petrochemical plant, Phase 1 of Masjed Soleiman and Parsian Sepehr became operational.

That along with the completion of 17 petrochemical projects brings the total number of petrochemical plants to 64. Furthermore, three logistics plants are operating in the petrochemical sector which is expected to yield $21.5 billion in revenue – a new record in this sector.

Iran’s petrochemical industry earned $9.4 billion in export revenue in the calendar year to March 2020, $8.1 billion of which it supplied to the Central Bank, i.e. 120% higher than committed.

Last calendar year the petrochemical industry’s revenue fell to $9 billion due to the COVID-19 pandemic. However, it supplied $6.4 billion in revenue, i.e. 170% higher than committed. In the current calendar year, petrochemical exports are expected to yield $14.2 billion in revenue, $8.2 billion of which would go to the Central Bank.

According to National Petrochemical Company (NPC) data, Iran’s petrochemical industry would be gaining $20 billion in revenue in the current calendar year, $14 billion of which would be from exports.

Petchem Megaprojects

The Persian Gulf Bid Boland project had remained hamstrung for years, but it was revived thanks to efforts made by Iranian engineers. Megaprojects placed the petrochemical industry and the Persian Gulf Petrochemical Industries Company (PGPIC) on a new direction in the upstream petroleum industry. The Bid Boland project is earning Iran $1.5 billion in annual revenue. Still more significantly, there would be no gas flaring by March 2023 and associated gas would be largely used as feedstock for petrochemical production.

The petrochemical industry has throughout its decades of activity supplied products whose number and diversity have been on the rise. Generally speaking, only in the feedstock supply sector, these projects have been in contact with the upstream sector. Efforts have been constantly under way to complete the cycle of products, supply a wider number of products and finally help realize the longtime dream of ending raw materials sales. That is why many petrochemical plants were banned from entering feedstock supply and other upstream domains. Specifically, after petrochemical plants were privatized under Article 44 of the Constitution, the gas with the upstream sector was widened as all oil resources are national wealth and exercising public sovereignty right over them lies with the Petroleum Ministry. However, the decision adopted by the Persian Gulf Bid Boland refinery in line with zero flaring and instead supply feedstock from this source opened a new way for petrochemical plants to be fed with flare gas.

Jafar Rabiei, CEO of PGPIC which operates the BB project, said: “The petrochemical industry has proven its capacity to join the upstream sector for its value chain supply.”

Of course, two new megaprojects, each worth $3 billion, are envisaged to come online by 2027.

He also said the ground had been paved for the two petrochemical megaprojects of Almas and Hormuz, totally worth $7 billion.

“The petrochemical industry is financially and technically able to operate upstream oil and gas projects. Two reasons may explain why. First, petrochemical plants, in addition to financial and technical capacity, are more motivated in feedstock supply and they can operate these projects based on a regular timeframe,” he said.

Rabiei said that the $4.5 billion Hormuz project would be fed with a combination of ethane and butane, which the giant South Pars gas field would supply.

Furthermore, construction of three megaprojects with combined feedstock would begin soon, which would help diversify petrochemical products. The propylene, methanol, ethylene, benzene and urea chains would be developed.

The Hormuz petrochemical megaproject, with an annual capacity of 5.8 million tonnes and $4.5 billion investment, would be fed with ethane and butane to produce varieties of polyethylene and polypropylene. A second project is operated by Visa Energy Arghavan in Assaluyeh with an investment volume of $1.6 billion with an output capacity of 1.8 million tonnes. The third project is the Arya Oil and Gas Company’s olefin project with an investment of $4.8 billion with an annual output capacity of 4.8 million tonnes.

Bright Future for Projects

A welcoming event in recent years has been that National Petrochemical Company (NPC) defined a second and third jump in a bid to complete remaining projects from previous years. This planning has continued regularly and what has remained from the second jump is ending, and parts of the third jump projects have started out. Eleven projects from the mix of second petrochemical jump have been left. Five projects would come online in the second half of the current calendar year and six others in the first half of next calendar year. There are currently 50 active projects in the petrochemical industry, 39 of which have come online in the third jump. The third jump projects would begin in the second half of next calendar year. With the completion of the third jump in the petrochemical industry, the capacity of this industry would reach 136 million tonnes annually. By 2027, the production capacity of the petrochemical industry would reach 167 million tonnes.

Last calendar year, most petrochemical projects became operational within the framework of the 6th Development Plan. Despite the coronavirus pandemic, 17 petrochemical projects came online in that year, adding 25 million tonnes to the country’s petrochemical production capacity. That is unprecedented as it has created job opportunities directly for 27,300 persons.

The significance of materialization of this objective is emanated from the fact that based on Article 44 of the 6th National Development Plan, the government is required to make planning to enhance the new petrochemical production capacity so that the petrochemical production capacity would reach 100 million tonnes. The important point is that the petrochemical industry capacity was below 62 million tonnes in 2016, but it increased to 83.5 million tonnes by last March. The figure is expected to reach 100 million tonnes in the current calendar year, which is the 5th year in the 6th National Development Plan.

The petrochemical industry has been able to supply domestic industry as well as downstream sector needs. Of the 35-million-tonne petrochemical mix, 10 million tonnes had been sold on domestic markets, which would generate jobs in 15,000 small and large-sized enterprises operating in the downstream petrochemical industry.

Petrochemical products have also witnessed diversity as more than 40 chemicals and about 340 grades of polymer products were supplied on the market last calendar year. More than 20 products would be added to the petrochemical mix by 2025. Meantime, these measures have directly resulted in the materialization of a big objective in the petrochemical industry. Once the third jump projects become operational, the petrochemical industry would receive 2 million barrels of oil equivalent a day (mboe/d) from the upstream sector, which shows the significant role of this industry in preventing raw materials sales. This issue takes up added significance when the figure would reach 2.3 mboe/d by 2027.

Meantime, with the continued development of the petrochemical industry in new hubs, three projects in the Parsian hub, three projects in Makran, four projects in Qeshm Island and two petro-refining projects in Jask would be instrumental in ending raw materials sales.

Flexibility

The petrochemical industry has a bright and long-term horizon before it. It would need precise planning up to at least 2027 and some commitments may be envisaged about the details of this performance. This planning has been envisaged regardless of the presence of a specific administration or person and is in full compliance with the general requirements of the petrochemical industry. Therefore, no change will occur even if the administrations or officials change.

Amir Vakilzadeh, director of NPC projects, said recently that even after a new administration has taken office no change would be envisaged in the third jump.

“All petrochemical industry projects have received basic agreement after the investor’s announcement of readiness and expert exam. Therefore, even with administration changes, projects are unlikely to be set aside,” he said.

By Masoumeh Asghari

Courtesy of Iran Petroleum

Your Comment