Here is the full text of the interview Mohammadi gave to "Iran Petroleum".

What are NISOC’s current plans for enhanced production?

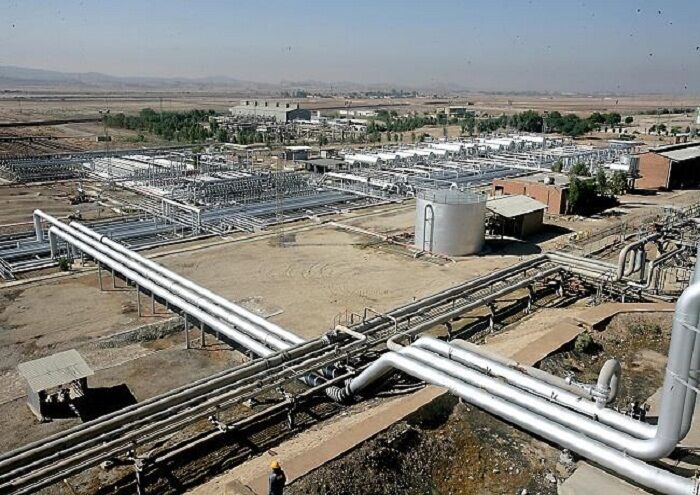

As plans designed in the past two years have materialized and new production capacity has been created thanks to engineers and technicians working at NISOC’s subsidiaries, the company is now ready to return to pre-sanctions production levels, i.e. that of before 2018. Following task assigned to it, NISOC has made necessary plans and forecast necessary resources to realize its production objectives in the current [calendar] year, which involves sustainable output lift. To that end, it has boosted its production capacity, and realization of such big objective would definitely require supply of services and logistics and removal of obstacles to production. With production capacity at more than 3 mb/d of oil, NISOC can supply 80% of Iran’s oil production. All operation sections and their subsidiaries – Karun, Maroun, Aghajari, Gacsharan and Masjed Soleyman production companies – have been instructed about output enhancement plans. As soon as sanctions are lifted and the ground is paved for increased oil exports, enhanced output would materialize.

What are requirements for increased production at NISOC-run fields?

That requires implementation of the rigline plan this year, stimulating wells, repairing pipes, carrying out enhanced production plans and increasing the saline oil processing capacity using prefabricated desalters. During the obligatory decline in production, the situation of wells, reservoirs and installations at NISOC-run areas are monitored constantly and necessary arrangements have been made for enhancing and maintaining the production capacity. In parallel with these measures, activities related to technical inspection, safety of installations and HSE regulations are under way for increased production.

Could you tell us about projects NISOC has so far implemented in order to increase production?

In order to maintain and enhance production, which has always been stressed by the minister of petroleum and CEO of National Iranian Oil Company (NIOC), NISOC signed 18 agreements with E&P companies last calendar year in two phases. The €2 billion agreements included the contract packages of Ahvaz 14, Maroun 3, Maroun 6, Maroun 14, Maroun 25, Ramin, Balaroud, Mansourabad, Zilaei, Siahmakan, Chelinger and Garangan, Bibi Hakimeh, Soulabdar, Binak, Gachsaran 34, Golkhari, Ahvaz 235 and Lali Bangestan.

For how many of these packages, have you started basic work?

We have started work for 11 packages including Ahvaz 14, Maroun 3, Maroun 6, Maroun 14, Maroun 25, Ramin, Balaroud, Mansourabad, Zilaei, Siahmakan, Chelinger and Garangan. Of 27 packages, 24 have been decided while operations are under way for 17 packages. Work will start on 7 others this year. Furthermore, three other packages including Pazanan, Gachsaran 12 and Qale Nar would be agreed upon by contractors this year.

How many drilling rigs are envisaged for these contracts?

Last calendar year, the number of operating rigs reached 14. With new agreements being signed, this figure is set to increase in the current calendar year.

In light of sanctions and the outbreak of the coronavirus pandemic, how much feedstock has NISOC managed to supply to refineries?

The plan for producing and delivering crude oil as feedstock to refineries has materialized both quantitatively and qualitatively in line with NIOC plan. The sanctions and the pandemic have not affected NISOC’s production plans. We have even seen success in this field. Guaranteed quality and timely supply of feedstock to refineries, energy stability and fuel production in the country is the outcome of implementing the project. NISOC has met 95% of its sustainable supply plan targets in feeding refineries across the country.

Which fields does success lie in?

Given the country’s need, several processing changes were made in NISOC installations to allow for the exchange of four grades of crude: light, heavy, ultra-heavy and synthetic from the transmission pipeline corridor of NISOC to consumer points. Before that, only light and heavy oil was transferred from NISOC-run reservoirs and fields and the oil received from other companies via the chain of installations and pipelines of this company. Following several design schemes and numerous processing changes, it has become possible to receive ultra-heavy crude oil supplied by West Karoun fields, as well as the synthetic oil received from the Bahregan terminal.

One important issue in NISOC-run areas is to feed the Persian Gulf Bid Boland gas refinery. How much feedstock was supplied to this refinery last calendar year?

NISOC-run areas are required to supply 2bcf/d of feedstock for the Persian Gulf Bid Boland gas refinery. Therefore, in the wake of coordinated arrangements with the Persian Gulf Petrochemical Industries Company (PGPIC), the necessary gas was supplied for the operation of the refinery last calendar year. This gas is pumped from the Aghajari and Gachsaran installations to Bid Boland. Engineering studies on some of these projects are now over and some have been awarded to domestic contractors. Other projects are currently in various phases of the process of bidding. By implementing these projects, in addition to economic and environmental benefits, more than 593 mcf/d of gas would be saved from flaring.

One important issue that was stressed at NISOC last calendar year was the use of pipelines owned by the company for an integrated management of South Pars condensate.

Yes, it was agreed to deliver the synthetic oil produced from South Pars gas condensate to the Abadan and Isfahan refineries. In this project, synthetic crude is received from Bahregan prior to being delivered to the Omidiyeh pumping station via NISOC pipeline. It will finally go to the Isfahan and Abadan refineries.

Would you please explain about measures taken by NISOC with regard to support for domestic manufacturing?

In parallel with production and development activities, NISOC has been seriously pursuing domestic manufacturing. Last calendar year, 30% of 7,500 items of commodities was domestically manufactured. That is highly significant. Through NISOC support, down-hole and seamless pipes were domestically manufactured by Iran National Industrial Group and the company made significant success in this regard.

How about supporting knowledge-based companies?

In application of Law on Supporting Knowledge-Based Companies and Maximum Use of Domestic Capacities, NISOC last year signed an agreement with a knowledge-based company. More agreements are expected in the current calendar year. Also under an agreement with Sharif University of Technology, NISOC envisages domestic construction of 100 Inflatable Retrievable Packers, a high-tech tool. In addition to that, agreements have been signed with domestic manufacturers on flare gas gathering.

What has been done with regard to cooperation with universities?

NISOC has always had good cooperation with universities. Last calendar year, we improved our cooperation with universities and scientific and research centers. To that effect, agreements were signed with Research Institute of Petroleum Industry (RIPI), Sahand University of Technology, Ferdowsi University, and Isfahan University of Technology for enhanced recovery from the Rag Sefid, Masjed Soleyman, Binak and Maroun fields. Furthermore, NISOC has signed a 5-year cooperation agreement with RIPI to carry out specialized projects in the upstream and downstream sectors. NISOC has also signed a memorandum with Sharif University of Technology for maximum use of technological and knowledge-based capacities in 20 technological sectors, whose positive impacts will come to the limelight for the petroleum industry in the future.

Eight opportunities for investment in skid-mounted oil processing facilities were recently unveiled. Would you please briefly introduce them?

Regarding enhanced oil production capacity by this company, prefabricated units are envisaged in the field of processing saline oil. Based on the Petroleum Ministry and NIOC's decision, technology companies may be used for units with capacity below 25,000 b/d. That may be achieved without having to go through bureaucracy. In this regard, purchase of services, supply, installation, operation, steering and maintenance of eight skid-mounted processing facilities have been introduced to attract cooperation of knowledge-based and technology-based companies. They are considered for the Ahvaz, Masjed Soleyman, Rag Sefid, Kupal and Ramshir oil reservoirs with a total capacity of 220,000 barrels. It is noteworthy that Bangestan reservoir of the Ahvaz field, Ramshir Field, the Asmari reservoir of the Masjed Soleyman field and Rag Sefid field, and the Bangestan reservoir of the Kupal field with more than 200,000 barrels of capacity would need skidding services at different levels of production, desalting, sweetening and pumping systems.

What measures have been taken by NISOC in terms of green production and development?

In line with Petroleum Ministry and NIOC policies on execution of environmental instructions for reducing environmental pollutants, NISOC eyes full gathering of flare gas. NISOC is currently operating several key agreements and one MOU for flare gas gathering. Their completion would put an end to gas flaring in the Aghajari, Ramshir, Pazanan, Rag Sefid and Maroun fields, which would in turn bring about positive environmental and economic results for the country. Meantime, based on the agreement signed with PGPIC, 26 subprojects are under way in three provinces: Khuzestan, Bushehr and Kohguiluyeh & Boyer Ahmad for the gathering of associated gas and supplying gas to the Bid Boland II gas refinery. Besides, NISOC is conducting the process of management of industrial waste in all processing units as part of its environmental obligations.

Last calendar year, we saw for the first time that the Bangestan reservoir of the Narguessi field reached production.

With the drilling of Well No. 13 in the Narguessi field as part of the 28-reservoir package, after completion in Sarvak Formation and making necessary arrangements, the Bangestan reservoir reached production with a flow of 3,000 b/d. Then, necessary planning started for complementary tests, measuring oil in place, recoverable deposits and development phases of the Bangestan reservoir.

What measures have been undertaken to reduce the energy consumption?

Enhanced energy costs, particularly in the industrial sector would have unfavorable impacts on organizational efficiency. Therefore, organizations would have to envisage a series of measures to obtain maximum productivity and save on energy consumption. In this regard, NISOC plans a 25MW decline in electricity consumption. For this purpose and in line with the resilient economy policy, particularly regarding reduction of energy intensity and preventing energy waste in different sectors, planning would be needed. In this regard, after carrying out comprehensive energy audit, prioritized and necessary solutions would be presented for implementation. Implementing an energy management system, regularly monitoring electricity consumption, installing smart electricity meters, installing double-glazed UPVC windows, installing energy-efficient lamps and LEDs, planning and supervising the functionality of ventilation systems, hiring energy inspection groups for peak hours, using drip irrigation system and using A and B-ranked equipment are among plans. Over recent years, NISOC has won praise from Power Distribution Company for energy efficiency. Furthermore, in the industrial and construction sector and without affecting the welfare level, about 10MW of electricity was saved by NISOC.

By Mahnaz Mohammad Qoli

Courtesy of Iran Petroleum

Your Comment