“Drilling is the starting point in the oil and gas value chain,” Mehran Makvandi said. “Without drilling, there is no access to hydrocarbon resources.” This complex and technical process enables access to oil and gas reservoirs deep underground and serves as the link between geology and production, playing a fundamental role in the country’s energy security.

The importance of drilling extends beyond resource extraction; the speed, precision, safety, and cost of drilling directly affect upstream project economics and return on investment.

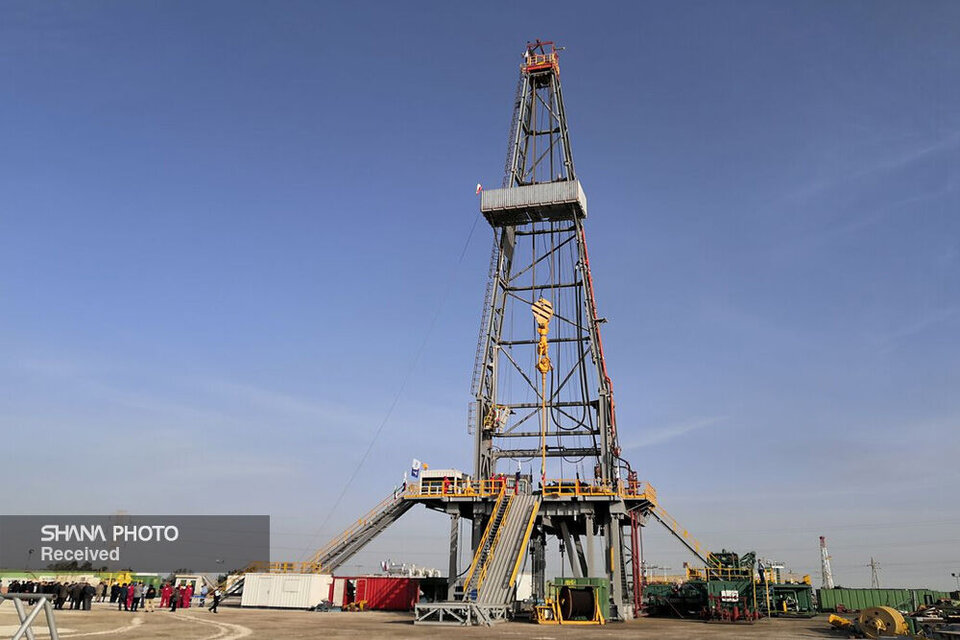

As a technology-based industry, drilling integrates modern engineering technologies, advanced equipment, and skilled professionals. Localizing rigs, critical components, and technical services—including cementing, drilling fluids, wireline logging, and well testing—not only reduces dependency on foreign suppliers but also generates jobs, facilitates knowledge transfer, and increases the oil industry’s resilience to sanctions. This is why strengthening drilling infrastructure has been a long-standing national energy policy priority.

Founded in December 1979, NIDC began operations with just six drilling rigs. Today, it operates dozens of land and offshore rigs and provides over 25 specialized technical services. Despite financial and technical challenges and international sanctions in recent years, the company has revitalized much of its capacity through modernization projects, technological upgrades, knowledge-based collaborations, and equipment localization efforts.

In an interview with Shana, Makvandi, CEO of NIDC, discussed the company’s past performance, future plans, interagency cooperation, and role in expanding the country’s oil and gas fields.

Drilling 100 wells in one year

Asked what led NIDC to successfully drill, repair, and complete 100 oil and gas wells in the Iranian year 1403 (March 2024–March 2025), Makvandi cited the use of 62 active rigs, the reactivation of two additional rigs, and improved interdepartmental coordination and efficiency.

“This included 24 development and appraisal wells, and 76 repair and completion operations,” he said. “It marks a significant leap forward given the economic and sanction-related constraints.”

He credited the reactivation of rigs—such as Rig 48 in Kharg and domestically manufactured Rig 73—as key contributors. Increased operational efficiency, minimized downtime, and reliance on domestic resources were the cornerstones of this achievement.

Strategic rig procurement plan

NIDC has been excluded from Iran’s privatization list under Article 44 of the Constitution, allowing it to reinvest in fleet renewal. The company, backed by the Oil Ministry and the National Iranian Oil Co., is now pursuing the purchase of 15 onshore drilling rigs with power capacities of 1,000 to 3,000 horsepower. The estimated investment is around $800 million.

“These rigs are specifically designed for exploratory and appraisal purposes and will be equipped with the latest technologies,” Makvandi said.

In addition, the company plans to procure specialized technical service equipment such as high-pressure pumps, formation testing tools, wireline logging equipment, coiled tubing units, and well-testing systems. A joint oversight committee has been established with NIOC’s integrated planning department to ensure alignment with the existing fleet.

Localization challenges, progress

Makvandi emphasized that equipment localization and boosting domestic manufacturing remain key strategic goals. The company has expanded partnerships with domestic manufacturers, such as Fajr Shiraz Complex, which has a track record of building core rig components.

The latest example, the third domestically built rig, saved \$7 million through efficient use of local engineering and resource management.

“Prioritization is based on field needs, project type—whether developmental, exploratory, or repair-related—and domestic manufacturing capacity,” he said. Challenges include limited technical infrastructure, the need for technology transfer, and timely access to high-quality components. However, the focus remains on reducing foreign dependency.

Highlighting innovation at Iran Oil Show

At the 29th Iran International Oil Show, NIDC signed two key contracts with new technology-based firms—one to produce nine one-megawatt generator motors and the other to manufacture four centrifuges for drilling fluid treatment. These technologies, once imported, will now be domestically produced to national standards.

The first units will be operational by year-end. A clear roadmap has been laid out for field deployment of these technologies, including ongoing collaboration with science and technology parks, universities, and knowledge-based firms. Field tests are already underway, focused on cost reduction, drilling precision, and faster well completion.

Strategic cooperation with NIOC exploration

NIDC also signed a memorandum of understanding with NIOC’s Exploration Directorate, assigning three high-power rigs—one at 3,000 horsepower and two at 2,000 horsepower—for use in exploratory operations. These rigs will feature advanced technology and support efforts to discover new oil and gas fields.

“Exploratory drilling is the starting point of every hydrocarbon field’s development,” Makvandi said. “This collaboration helps accelerate timelines and improve drilling quality, especially in remote or border regions.”

Regular coordination meetings are underway, and plans include rig customization for exploratory missions and deployment of specialized field teams.

Strengthening engineering, HSE

Makvandi said the company is committed to strengthening its engineering capabilities. This includes upgrading design software, continuous training, localized technical guidelines, and the use of real-time drilling monitoring systems. The company’s drilling study unit is now more active in providing project-specific technical consultations.

In terms of health, safety, and environment (HSE), NIDC has promoted a safety-first culture, held specialized training for field personnel, and upgraded safety systems on rigs. To reduce operational delays, the company established a non-productive time (NPT) analysis committee and implemented performance evaluation systems and effective collaboration with field operators.

Future outlook: Digital transformation, modernization

Makvandi believes that international engagement would further benefit the company—not only through easier access to advanced equipment but also by enabling international training programs, certifications, and potentially exporting drilling services.

Recent investments and contracts reflect accelerating development and modernization in Iran’s drilling sector. Over the next five years, NIDC’s strategic focus areas include:

- Fleet modernization, with a focus on new land and offshore rigs.

- Expansion of offshore drilling, particularly in Persian Gulf fields.

- Upgrading and integrating technical service equipment for faster, more accurate operations.

- Digitalization of drilling processes, from design and monitoring to data analysis and management, to improve decision-making, safety, and cost-efficiency.

- Stronger partnerships with scientific and knowledge-based institutions.

- Human capital development and enhancing international competitiveness.

The company has already reduced non-productive time from 21% to 9.6% and aims to cut it below 3% by 2029.

Amir Eftekharipour

Your Comment